Laboratory. Quality control of performs and caps

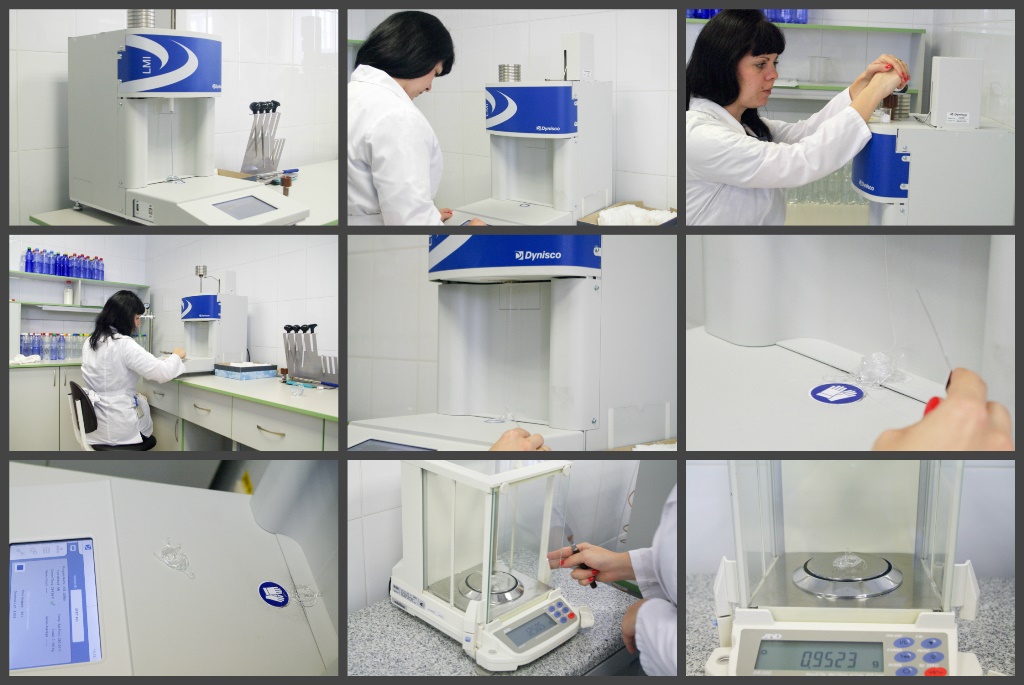

The quality control division of "Plastiform , Ltd." consists of an analytical laboratory and production one. The quality of manufactured products is ensured in three stages:

Entry control

Routine control during the production process

Acceptance tests

1. The object of the entry control is in controlling PET-granules for their compliance with the standard documentation for such parameters as: appearance, foreign bodies inclusions content, polymer granules heterogeneity, humidity, viscosity, melting point, acetate aldehyde content.

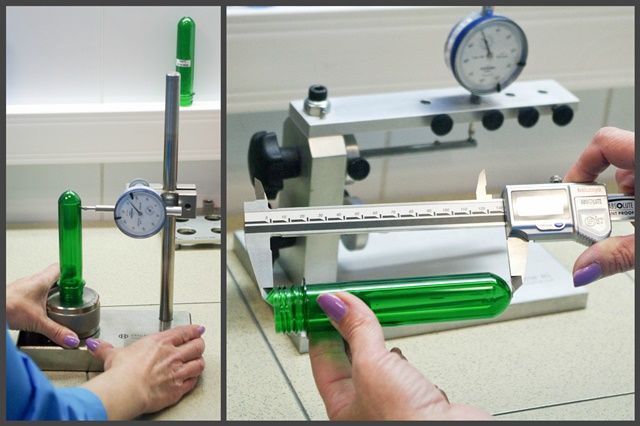

2. The object of the routine control is a continuous control of products by means of visual and instrumental methods. The laboratory is equipped with measuring gages of well known foreign companies.

3. The object of acceptance tests is in performing the exit control in conformity with standard documentation.

Control of preforms

PETF-preforms are controlled at the laboratory in conformity with the specification TU 2297 001-69382110-2012 for the parameters listed below:

- appearance;

- colour;

- geometric parameters;

- performs weight;

- presence of visual defects;

- curvature and variation in thickness;

- AA content;

- viscosity;

- colorant migration.

Polymer caps control

Polymer screw caps are controlled at the laboratory in conformity with the specification TU 9299-002-69382110-2012, TP TC 005/2011 for the parameters listed below:

- appearance;

- colour;

- geometric parameters;

- weight;

- painted coating adhesion;

- tightness of closure;

- torque quantity.