The PET-preform as a blank for the PET-bottle

Blanks, i.e., PET-preforms are used for manufacture of plastic bottles. PET-preforms are processed into plastic bottles upon preheating by means of blowing.

PET-preforms are manufactured by us of polyethyleneterephthalate in conformity with the specification TU 2297-001069382110-2012.

Due to ever more growing amounts of production, the demand in the modern food industry for cheap quality containers for products is extremely high. Such containers must be in conformity both with the sanitary and hygienic requirements and conditions of storage and transportation, but they are not expected to require sophisticated and expensive production and recycling processes.

Containers of polyethyleneterephthalate (PET) meet these requirements in the best way. PET is a transparent thermoplastic, strong and resistant to chemical substances impact, which grows yielding to processing when heated.

Due to its low weight, high transparency and simplicity in processing, as well as relatively low raw material cost, PET is an excellent material for plastic bottles manufactured from PET-preforms. Today exactly these containers are widely used in the food industry ( production of car-bonated and noncarbonated water, milk products, juice, soft, strong and slightly flavoured with spirits drinks), as well as in other fields of industry.

Technological advantages of the "PlastiForm" PET-preforms:

The new improved Capello design makes it possible to considerably increase the productivity (at the expense of reduction in the time of the preform preheating). The total operational length and wall thickness aren’t changed.

The perform’s parameters make it possible to ensure quality manufacture of bottles by means of any equipment.

Precise maintenance of basic parameters in manufacturing PET-preforms brings the possibility of off-grade products occurrence to zero.Точное соблюдение основных параметров при выпуске преформ ПЭТ сводит возможность производственного брака к нулю.

PET raw material and PET-preforms manufactured of it are subjected to mandatory hygienic certification (due to their use as containers for food products).

PET-preforms are manufactured in conformity with the specification TU 2297-001069382110-2012.

Wholesale deliveries of preforms

The "PlastiForm" plant carries out wholesale deliveries of performs. Various versions of wholesale deliveries are possible.

Table of "PlastiForm, Ltd" PET-preforms product mix in relation to the weight of the finished PET-bottle with the neck of the standard PCO1881

Volume of fi-nished PET bottle |

0,33-0,5 l |

0,33-0,5 l |

0,33-0,5 l |

1-1,5 l |

1-1,5 l |

1,5 l |

PET-preform weight PCO1881 |

17,5 g |

19,4 g |

20,7 g |

31,2 g |

33,6 g |

34,8 g |

|

The new improved design Capello enables the manufacturer to increase the productivity of the blowing equipment at the expense of reduction in the time of the perform preheating. |

Basic parameters

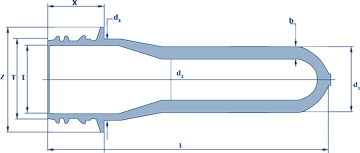

Geometric dimensions of the preforms

| PREFORM TYPE | Weight, г | L, mm | X, mm | b, mm | d1, mm | d2, mm | d3, mm | Z, mm | T, mm | I, mm |

| 17,5 PCO 1881 | 17,5±0,3 |

98,05±0,50 |

17,05±0,25 | 2,0±0,19 | 22,1±0,27 | 22,61±0,15 | 25,5±0,15 | 33,0±0,15 |

25,07±0,3 | 21,74±0,13 |

| 19,4 PCO 1881 | 19,4±0,3 | 98,0±0,50 | 17,0±0,25 | 2,43±0,19 | 22,1±0,27 | 22,61±0,15 | 25,5±0,15 | 33,0±0,15 | 25,07±0,3 | 21,74±0,13 |

| 20,7 PCO 1881 | 20,7±0,3 | 98,0±0,50 | 17,0±0,25 | 2,70±0,19 | 22,1±0,27 | 22,61±0,15 | 25,5±0,15 | 33,0±0,15 | 25,07±0,3 | 21,74±0,13 |

| 31,2 PCO 1881 | 31,2±0,4 | 129,0±0,65 | 17,0±0,25 | 2,60±0,19 | 25,76±0,27 | 26,61±0,15 | 25,5±0,15 | 33,0±0,15 | 25,07±0,3 | 21,74±0,13 |

| 33,6 PCO 1881 | 33,6±0,3 | 129,0±0,5 | 17,0±0,25 | 2,96±0,19 | 25,80±0,27 | 26,61±0,15 | 25,5±0,15 | 33,0±0,15 | 25,07±0,3 | 21,74±0,13 |

| 34,8 PCO 1881 | 34,8±0,4 | 129,0±0,65 | 17,0±0,25 | 3,11±0,19 | 25,76±0,27 | 26,61±0,15 | 25,5±0,15 | 33,0±0,15 | 25,07±0,3 | 21,74±0,13 |